The Main Raw Materials For Making Clothes

Clothes are now created from a diverse range of materials. Plants and animals are still used to make traditional textiles like cotton, linen, and leather. However, most garments are constructed of substances and chemical compounds obtained from crude oil derived from fossil fuels.

Bangladesh’s largest foreign currency earner, the garment sector, is suffering from coronavirus-related supply chain disruption, with raw material costs skyrocketing.

According to a report by the Bangladesh Trade and Tariff Commission (BTTC), Bangladesh imports 60 percent of its woven fabrics from China. According to the survey, China supplies 15-20% of raw resources and 80-85 percent of coloring chemicals and accessories to the knitwear industry. Every year, China provides around 40% of the raw materials for clothing items and the packaging production business.

Three essential causes have increased Bangladesh’s textile industry’s growth. The country is rich in resources, opportunities, and government policies that are helpful. A huge number of laborers may be found in Bangladesh. Natural gas and energy are also inexpensive. Bangladesh has an edge in creating labor-intensive items because of its large population.

Polyester fabrics, fabrics derived by man-made fibers, Polyviscose fabrics, viscose thread fabrics, and other textiles make up the majority of its exports. Knitted or woven shirt, tops, pants, skirts, shorts, sweaters, and sportswear clothing make up the majority of apparel exports. A vast number of people are employed in the handloom sector, which also manufactures fabrics for the local market. Despite being one of Bangladesh’s fastest-growing and largest industries, it confronts some difficulties.

The Main Raw Materials In The Garment Industry Of Bangladesh

Cotton, Muslin, Tant, Rajshahi silk, Jamdani, and khadi are the most common raw materials used in the textile and garment industries.

Cotton:

Bangladesh comes as the second largest user of cotton in Asia. Apart from importing, cultivation of cotton began in 20 to 22 districts of Bangladesh. This only covered 0.55 percent of the total land space of 81 lakh hectares, which was allowed to be cultivated.

Cotton is the backbone of Bangladesh’s RMG industry, with our nation being among the top four users of this miraculous fiber in the world. China, India, and Pakistan are the other three, with the latter two having major home textile markets. Cotton is the primary raw material used in Bangladesh’s garment export sector.

However, Bangladesh still imports cotton because imported cotton is usually cheaper, since bought in bulk, and sometimes they have variations.

Muslin:

This fabric of Dhaka was very well known since 18th The basic material of making muslin was cotton fabric, however other forms may include silk and viscose as well.

Early muslin was woven by hand with unusually fine handspun yarn. For most of the 17th and early 18th centuries, it was transported from Bengal into Europe.

Tant:

This fabric gained its popularity due to the sari made by the fabric. Tant sari is a traditional Bengali sari that originated in the Bengal region of India’s eastern region and is worn by Bengali ladies. Tant saris are weaved from cotton strands and are known for their transparency and lightness. It is thought to be the most comfortable sari for the Indian subcontinent’s hot and humid climate.

Tant sari weaving is a well-known and centuries-old Bengali skill. The artisans weave the cotton into thread, which is then woven into a tant sari. This is done with the help of two shuttles. Weavers employed handlooms in the past, but power looms have now mainly overtaken them in the production of these saris.

Rajshahi Silk:

Rajshahi silk refers to silk products made in the Bangladeshi city of Rajshahi. It is well-known for being a high-quality fabric for garments, particularly saris.

Silk processing in the region dates back to the 13th century, according to records. Bengal silk or Ganges silk were the names given to it at the time.

Saris manufactured of Rajshahi silk are extremely popular throughout Bangladesh. Rajshahi silk is indeed marketed to designers as fabric, and it comes in a variety of colors and patterns.

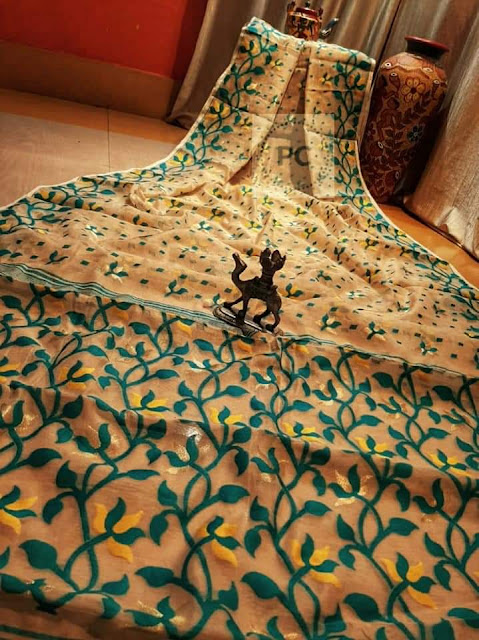

Jamdani:

This is a fine muslin textile with various patterns, manufactured for generations in Bangladesh’s South Rupshi area, on the banks of the Shitalakhwa river. The fabric is typically woven using a mix of gold and cotton threads.

Jamdani was formerly known as Dhakai, after Dhaka, one of the Bengal region’s numerous ancient textile weaving centers.

Jamdani is perhaps the most pricey loom product since it demands the greatest time and effort. It patterns are generally geometric, botanical, and floral designs that are supposed to have been passed down through the generations. Only aristocratic and royal families could afford such luxuries because of the extremely meticulous methodology required.

Khadi:

This fabric has a prolonged history in Bangladesh. Marco Polo, who lived in the 12th century A.D., characterized Khadi from the Region of Bengal as even finer than a spider’s web. The Bengal Khadi Muslin was also a favorite of the Romans, who used to import large quantities of the cloth.

Khadi or khaddar is a cotton-based hand-spun and hand-woven fabric from India, Bangladesh, and Pakistan. The cloth is usually made of cotton, but it may also contain silk or wool, which are all spun back into yarn on a charkha spinning wheel. It’s a versatile fabric that keeps you cool in the summer and toasty in the winter. Khaddar is occasionally starched to offer a firmer feel in attempt to optimise its appearance. In the fashion world, it is widely accepted.